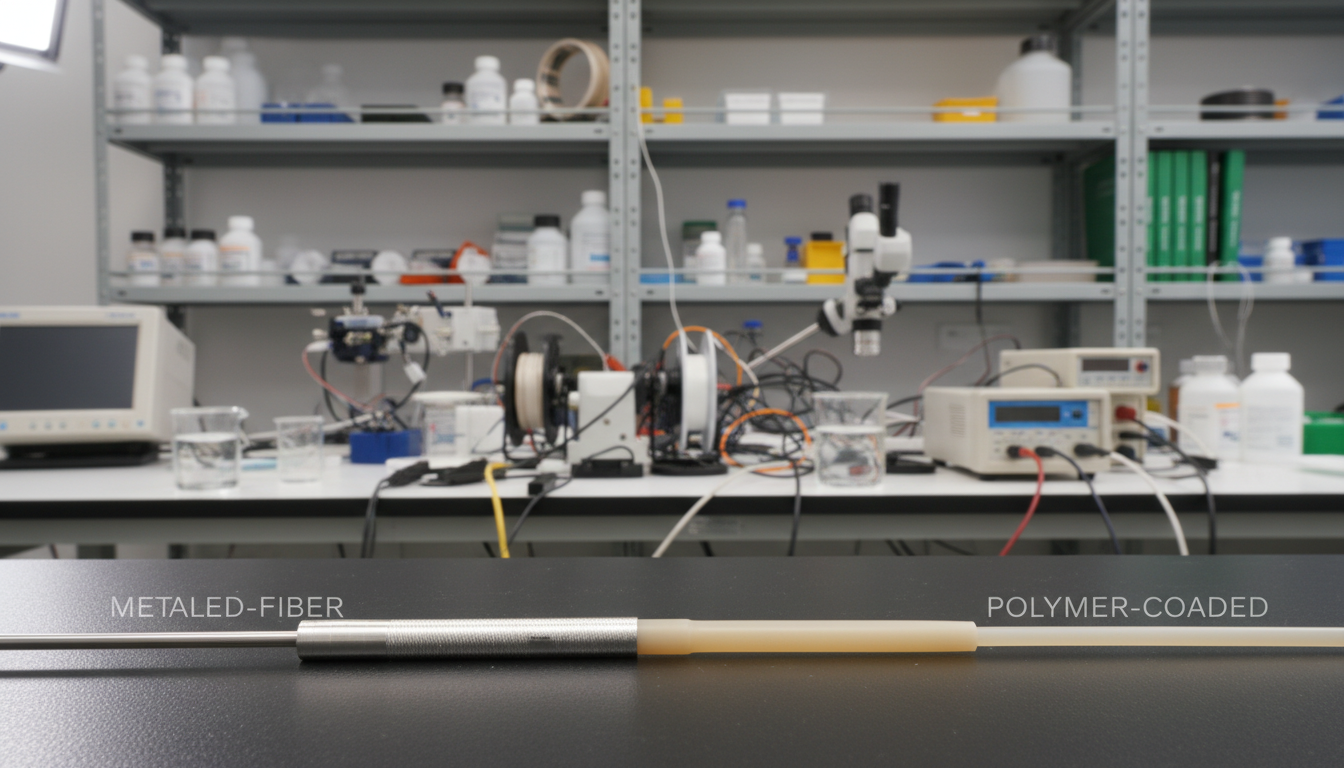

The world of advanced materials has changed how engineers solve design problems. Metal coated fiber and polymer-coated options lead this change. They mix fibers with protective coatings, making them stronger than traditional metals in many uses.

Companies like Boeing and Tesla use these fibers in their products. They are strong but much lighter than steel or aluminum. The coatings protect the fibers from damage by moisture, saltwater, and harsh chemicals.

Hexcel and Toray Industries engineers use these materials for various needs. They make electrical insulation boards and drone frames. The auto industry uses them for lightweight parts. Marine makers build boats and platforms that resist corrosion.

Choosing between metal and polymer coatings affects more than just how well they work. Cost, how hard they are to make, and their impact on the environment also matter. Knowing these helps engineers pick the right material for their projects.

Key Takeaways

- Coated fibers are stronger and lighter than metals like steel and aluminum

- Metal coatings are best for electrical needs in aerospace and electronics

- Polymer coatings are great for resisting chemicals and bending in cars and boats

- Both types keep the fibers safe from moisture, chemicals, and damage

- Choosing a material depends on what you need, your budget, and the environment

- They are used in everything from aircraft parts to electrical boards and custom cases

Introduction to Coated Fibers

Coated fiber technology is a big step forward in materials science. It turns simple fibers into top-notch components with thin protective layers. These layers, made of metals or polymers, boost the fibers’ electrical, mechanical, and environmental strengths.

Coated fibers are used in many fields, from aerospace to medical devices. In areas like electric cars and airplanes, cutting down on weight is key. Saving just one pound can mean better fuel use and longer battery life. Gold coated fiber and similar materials offer strength without adding extra weight.

Today’s fiber protection systems fight off many environmental dangers. Sunlight’s UV rays can damage materials over time. Chemicals in factories can weaken them. And moisture can make them less strong. Coated fiber tech tackles these issues with smart, designed layers.

| Coating Type | Primary Protection | Common Applications |

|---|---|---|

| Gold Coated Fiber | Electrical conductivity | Electronics, sensors |

| Aluminum coating | Thermal resistance | Aerospace components |

| Polymer coating | Chemical resistance | Medical devices |

For special uses, you need special materials. MRI machines need non-magnetic parts to avoid messing with images. Electronic cases need to block EMI to keep signals clear. And robots need light parts that stay strong even when stressed a lot.

Overview of Metal Coated Fiber

Metal fiber technology is a big step forward in making materials for electrical and industrial use. It mixes the flexibility of regular fibers with the great conductivity of metal coatings.

Metals like nickel, gold, aluminum, and copper are used for these coatings. Each metal adds special qualities to the fibers. Nickel coated fiber is great because it conducts well and doesn’t rust easily, perfect for tough places.

Metal fiber technology is used in many fields. It’s great for blocking electromagnetic interference (EMI) to protect electronics. The metal coating acts as a shield, stopping electromagnetic waves.

| Metal Type | Conductivity Rating | Primary Applications |

|---|---|---|

| Nickel | High | EMI shielding, gaskets |

| Gold | Excellent | Medical devices, sensors |

| Aluminum | Good | Lightweight cables, aerospace |

| Copper | Excellent | Power transmission, grounding |

Coatings made of conductive fibers have big benefits over solid metals. They keep electrical connections in flexible setups and help with grounding. They also work well when bent or flexed many times. The coating process lets makers get precise conductivity levels and keeps the material much lighter than solid metals.

Overview of Polymer Coated Fiber

Polymer coating systems turn regular fibers into useful composite materials. These coatings are made of epoxy, polyester, or vinyl ester resins. Each type has its own benefits for different uses.

Epoxy resins are top for sticking power and lasting durability. They’re great for making parts for semiconductors. Polyester coatings are cheaper and work well for most uses. Vinyl ester resins are best in tough chemical settings where others might not last.

Unlike aluminum coated fiber, which is good for carrying electricity, polymer-coated fibers focus on safely releasing static electricity.

How well these coatings handle heat varies. Standard plastics can take up to 120°C (248°F). But, special epoxies can handle over 180°C (356°F). This makes them ideal for electronics work.

| Resin Type | Max Temperature | Primary Application | Key Benefit |

|---|---|---|---|

| Standard Epoxy | 120°C | Electronics Handling | Strong Adhesion |

| High-Temp Epoxy | 180°C | Semiconductor Processing | Heat Resistance |

| Vinyl Ester | 150°C | Chemical Systems | Chemical Resistance |

| Polyester | 110°C | General Purpose | Cost Efficiency |

These coated fibers are key in many areas. They’re used in powder handling, fuel processing, and chemical plants. Their ability to manage static electricity is a big plus, unlike aluminum coated fibers.

Performance Metrics: An Introduction

When checking coated fibers for industrial use, knowing key performance indicators is key. Fiber performance testing uses standard measurements. This gives consistent data for different materials and suppliers.

Important coating specs include several key properties. Tensile strength shows how much pulling force a fiber can handle before breaking. Flexural strength shows how well it resists bending. Temperature resistance is based on the glass transition temperature, showing the max operating conditions for each fiber.

Industrial fiber metrics go beyond just mechanical properties. Volume resistivity shows how well a fiber carries electrical charge. Surface resistivity tracks charge movement on the fiber’s surface. These are key for static dissipation or electromagnetic shielding.

| Test Standard | Property Measured | Typical Units |

|---|---|---|

| ASTM D790 | Flexural Strength | MPa or psi |

| ISO 527 | Tensile Strength | MPa or psi |

| ASTM D257 | Volume Resistivity | Ohm-cm |

| ASTM D638 | Elongation at Break | Percentage |

Fiber orientation greatly impacts performance. Woven fabrics offer balanced strength in multiple directions, great for complex stress patterns. Unidirectional tapes have maximum strength along one axis, ideal for predictable load paths. Density in grams per square centimeter helps in weight savings for aerospace and automotive.

Strength and Durability Comparison

Choosing fibers for tough jobs means looking at their strength and durability. Metal coated fibers can handle extreme temperatures that would melt other materials. They are heavy, adding up to 2.5 grams per cubic centimeter, but they protect well against damage.

Polymer coated fibers do well in environmental resistance tests. Carbon fiber reinforced polymers have tensile strength between 600 and 1,000 megapascals. Fiberglass alternatives have 150 to 300 megapascals. These coatings resist rust and corrosion, even in wet or salty conditions.

Standard polymers can handle up to 120°C. But some special ones can go over 180°C.

| Coating Type | Tensile Strength (MPa) | Temperature Limit | Weight Impact |

|---|---|---|---|

| Carbon Fiber Polymer | 600-1,000 | 120-180°C | Minimal increase |

| Fiberglass Polymer | 150-300 | 120°C | Light addition |

| Metal Coating | Variable | Extreme ranges | 1.8-2.5 g/cm³ |

UV exposure is a big problem for both coating types. Sunlight can damage surfaces, so they need protection outside. Engineers focus on stress points like notches and sharp corners. These areas can fail, even with added stiffness.

Electrical Conductivity in Coated Fibers

Choosing the right coated fibers for electrical use is key. Metal fiber coatings are top-notch for tough tasks. They offer great results.

Metal-coated fibers are great at conducting electricity. Silver and copper coatings are the best for this. They help in EMI shielding by creating a path for current flow.

Polymer coatings work differently. They use filler systems like carbon black or nanotubes. The fillers need to connect to work well.

| Coating Type | Conductivity Range | Best Application |

|---|---|---|

| Silver-coated fiber | 10⁵ – 10⁶ S/m | High-frequency shielding |

| Copper-coated fiber | 10⁴ – 10⁵ S/m | General EMI protection |

| Carbon black polymer | 10² – 10³ S/m | Static dissipation |

| Carbon nanotube polymer | 10³ – 10⁴ S/m | Flexible electronics |

Contact resistance is very important for metal fiber conductivity. The quality of the surface, how much pressure is applied, and temperature changes all affect how well it works.

Cost Analysis of Coated Fibers

When you’re planning your next project, it’s key to know the cost difference between metal and polymer coatings. The price can change a lot based on the coating type and quality you choose.

Metal-coated fibers are pricier because of the complex making process. They need special tools and skilled workers, which raises the cost. The price comparison shows metal coatings are 40-60% more expensive than polymer ones at first.

Polymer-coated fibers are more affordable. They cost between $15-45 per square foot. This makes them a good choice for big projects. Think about both the upfront cost and the long-term benefits when you’re deciding.

| Coating Type | Initial Cost Range | Maintenance Cost (Annual) | Expected Lifespan |

|---|---|---|---|

| Polymer Coating | $15-45 per sq ft | $2-5 per sq ft | 10-15 years |

| Metal Coating | $25-75 per sq ft | $1-3 per sq ft | 20-30 years |

It’s not just about the price. Metal coatings might cost more at first, but they last longer and need less upkeep. On the other hand, polymer coatings are better for tight budgets or projects that need updates often. Figure out the total cost over the project’s life to choose wisely.

Flexibility and Ease of Use

The flexibility of coated fibers is key for many uses. How well they work depends on the processing method. This affects how easy they are to make and how good they turn out.

Polymer-coated fibers are easier to work with than metal-coated ones. They can be cut and drilled with common tools. Using the right saw blades and drill bits keeps the coating safe.

Metal-coated fibers need special care because of their stiff coatings. This makes them hard to bend and requires special tools. The type of metal coating affects how hard it is to process:

| Coating Type | Processing Difficulty | Tool Requirements | Flexibility Rating |

|---|---|---|---|

| Aluminum Coating | Medium | Diamond-tipped tools | Moderate |

| Copper Coating | Medium-High | Specialized cutters | Limited |

| Polymer Coating | Low | Standard tools | Excellent |

| Nickel Coating | High | Industrial equipment | Poor |

Getting the right surface finish is important. The way fibers are processed can affect this. Each step in making the fibers impacts how well they work. So, controlling the process is vital for quality.

Environmental Impact of Coatings

Choosing between metal and polymer fiber coatings is more than just about performance. It’s also about the environment. Both types have their own challenges for environmental compliance and meeting sustainability goals.

Polymer coatings are under the spotlight because of volatile organic compounds (VOCs) they release. These emissions must be closely watched to follow EPA and state air quality rules. On the other hand, metal coatings don’t have VOC issues but pose problems with heavy metal disposal and recycling.

Rules and regulations play a big role in choosing coatings. The European Union has REACH and RoHS rules that limit harmful substances in eco-friendly materials. In the U.S., OSHA sets standards for coating dust exposure and ventilation needs for both types.

| Coating Type | Recyclability Rate | VOC Emissions | Disposal Method |

|---|---|---|---|

| Aluminum Coating | 85-90% | None | Metal recycling facilities |

| Copper Coating | 80-85% | None | Specialized e-waste centers |

| Acrylate Polymer | 15-20% | 50-150 g/L | Industrial waste management |

| Silicone Polymer | 10-15% | 25-75 g/L | Chemical waste processing |

More and more factories are turning to sustainable fiber coatings to lessen their environmental impact. Water-based polymers cut down VOCs without losing protection. Bio-based polymers, made from plants, are also seen as good alternatives to oil-based coatings.

Conclusion: Making the Right Choice

Choosing the right coated fiber starts with knowing what you need. This guide helps you find the right coating for your project. Companies like Corning and OFS are great for structural support. Prysmian Group is top for thermal insulation.

Deciding between metal and polymer coatings depends on your needs. Do you need to block electromagnetic signals, resist chemicals, or be lightweight? Your choice affects how your project works.

When choosing, think about the load and environment your fiber will face. Metal coatings from AFL Telecommunications are best for aerospace and defense. They handle extreme temperatures but are heavy and need special tools.

Polymer coatings from Hexcel Corporation are great for marine and industrial uses. They resist corrosion and are easier to handle, saving money.

Both coatings have their own role in fiber optic systems. Before buying, check the manufacturer’s data on mechanical and electrical specs. Suppliers like CommScope and Furukawa Electric offer detailed info and traceability.

For indoor use, epoxy coatings are often best. For outdoor, vinyl ester coatings are better for chemical resistance.

The best choice balances performance and cost. Metal coatings are worth the extra cost for conductivity and shielding. Polymer coatings are better for general use where flexibility and cost are key.

Your final choice should match your project’s needs and budget. Think about the fiber’s strength, flexibility, and where it will be used.

FAQ

What are the main differences between gold coated fiber and nickel coated fiber?

Gold coated fiber is great for high-end electronics and medical use because it resists corrosion well and conducts electricity well. Nickel coated fiber is more affordable and works well for many industrial uses. It’s not as good as gold at resisting oxidation, but it’s cheaper.

How does aluminum coated fiber compare to polymer coated options for weight-sensitive applications?

Aluminum coated fiber is light and good at conducting electricity and shielding from EMI. But, polymer coated fibers are even lighter, making them great for drones and robotics. Aluminum is better for electrical needs, but polymer is better for saving weight.

What temperature ranges can different coated fibers handle?

Polymer-coated fibers can handle up to 120°C with standard epoxy resins. High-temperature epoxy can go over 180°C. Metal coatings like nickel, gold, and aluminum can handle even higher temperatures.

For very high heat, vinyl ester polymer coatings are best. They work well in semiconductor handling and chemical processing.

Are metal coated fibers suitable for outdoor marine environments?

Yes, metal coated fibers do well in saltwater. Gold is best for saltwater resistance but is expensive. Nickel is a good choice for its corrosion resistance at a lower cost.

Polymer-coated fibers with vinyl ester resins are even better for saltwater. They’re popular for boat hulls and marine structures.

What safety precautions should I take when working with coated fibers?

Always wear gloves and eye protection when cutting coated fibers. Use a respirator when sanding to avoid dust. Make sure metal coated fibers are grounded to avoid static.

Check if your materials meet VOC regulations indoors. Follow OSHA guidelines for dust exposure in industrial settings.

How do I choose between carbon fiber and fiberglass with different coatings?

Carbon fiber is strong and good for high-performance uses, but it’s expensive. Fiberglass is cheaper and works well for less demanding tasks. Add metal coatings for EMI shielding or electrical needs.

Polymer coatings are good for corrosion resistance and easier to work with.

Can coated fibers be recycled or disposed of easily?

Most coated fibers are hard to recycle and need special disposal. Metal coatings can be recycled at special facilities. Polymer-coated fibers usually go to landfills or energy recovery.

Always follow local regulations and EU directives for proper disposal.

What’s the typical lifespan of coated fiber materials in industrial applications?

Coated fibers can last 20-30 years or more in industrial use. Polymer-coated fibers need little maintenance. Gold coated fiber lasts long in corrosive environments.

Nickel and aluminum coated fibers may need checks in harsh conditions. Their long life makes them worth the initial cost.