Our Approach Is Built on Precision, Stability & Absolute Process Control.

Medical-Grade Specialty Optical Fiber Manufacturing

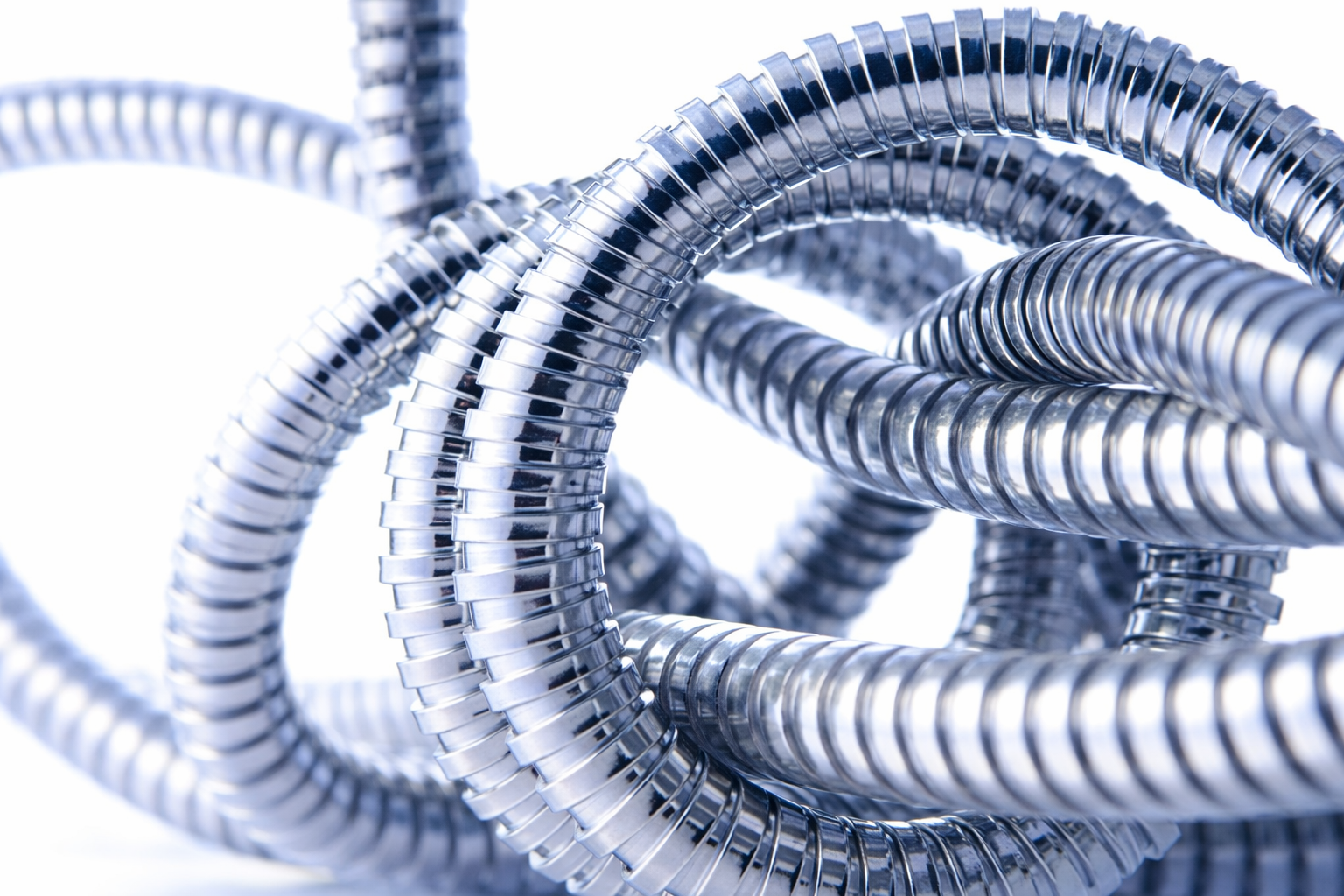

Medical environments demand materials that combine optical performance, sterilization compatibility, and absolute reliability. Our specialty optical fibers are manufactured to meet the strict requirements of medical devices, surgical systems, and diagnostic instruments where accuracy, hygiene, and durability are non-negotiable.

We produce metal-coated, spun, multi-core, and fully customized optical fibers designed to operate in high-temperature sterilization cycles, chemically aggressive cleaning processes, and mechanically demanding clinical environments. These fibers are used in minimally invasive surgery, medical imaging, laser delivery systems, and advanced diagnostic equipment.

Every production stage—from preform engineering to coating, inspection, and validation—is controlled to guarantee consistent optical transmission, tight dimensional tolerances, and full material traceability. Our medical fibers are built to integrate seamlessly into regulated medical manufacturing environments.

Medical Fiber Manufacturing – Engineered for Sterility and Stability

Modern medical devices operate under conditions that challenge conventional fiber coatings. Autoclave sterilization, plasma cleaning, chemical disinfectants, and repeated mechanical handling can degrade standard polymer fibers. Our specialty fiber technologies eliminate these risks through advanced metal and hybrid coatings that provide:

- Exceptional thermal resistance for autoclave and dry-heat sterilization

- Biocompatible surface materials

- Stable optical transmission after repeated sterilization cycles

- Mechanical durability for surgical manipulation

- Controlled surface cleanliness for medical-grade assembly

We manufacture fibers that support long-term clinical use without optical drift, coating degradation, or contamination risk.

Medical-Optimized

Fiber Engineering

Our fibers are engineered using predictive modeling for thermal expansion, sterilization stress, and coating adhesion to ensure stable performance in surgical and diagnostic environments.

Certified Medical Manufacturing Control

All medical fibers are produced under controlled conditions with documented materials, validated processes, and optional

medical compliance documentation.

Typical Medical Applications

Available Fiber Types

- Metal-coated fiber for sterilization-resistant systems

- Spun fiber for strain-insensitive medical sensing

- Multi-core fiber for compact imaging and signal distribution

- Fully customized fiber geometries and coatings

Technical Performance Summary

| Parameter | Fiber Sepcification |

|---|---|

| Coating Type | Medical-grade metal coatings (Gold, Titanium, Nickel, Copper, hybrid alloys) |

| Maximum Operating Temperature | Up to 400 °C continuous, higher for short sterilization exposure |

| Sterilization Compatibility | Steam autoclave, plasma, UV, chemical disinfectants |

| Biocompatibility | Non-toxic, non-reactive coating materials available |

| Coating Thickness | 5 – 40 µm, customizable |

| Fiber Diameter Tolerance | ±0.3 µm standard, tighter on request |

| Tensile Strength | > 500 MPa after coating |

| Bend Radius | As low as 20× fiber diameter |

| Thermal Shock Resistance | Stable under repeated sterilization cycles |

| Chemical Resistance | Resistant to alcohols, peroxides, acids, cleaning agents |

| Optical Attenuation Stability | No measurable drift after sterilization |

| Surface Cleanliness | Medical-grade controlled contamination levels |

| Production Traceability | Full batch, material, and process traceability |

| Custom Geometry Support | Single-core, spun, multi-core, hybrid structures |

| Length Availability | Prototype to kilometer-scale production |

| Compliance Options | ISO manufacturing, medical documentation support |

Q&A

Metal coatings provide superior resistance to high temperatures, sterilization chemicals, and mechanical wear. Unlike polymer coatings, they do not degrade during autoclave cycles and maintain stable optical performance over long service life.

All medical fibers are manufactured under controlled environments with surface cleanliness monitoring, material documentation, and optional medical compatibility validation.

Yes. Our fibers are engineered to maintain optical transmission, coating adhesion, and dimensional stability after hundreds of steam, plasma, or chemical sterilization cycles.

Absolutely. We manufacture fibers with ultra-tight diameter tolerances, small bend radii, and high mechanical strength, making them ideal for endoscopes, laser probes, and catheter-based systems.

Yes. We specialize in custom fiber geometries, coatings, and optical structures to match the exact mechanical, thermal, and regulatory requirements of medical device manufacturers.